Panel

The Steel Panel Radiator of ALL THERM, a powerful Radiator for Home Central Heating of highest steel quality, ideal for the new construction and refurbishing thanks to its high temperature performance. The Steel Panel Radiator guarantees a lower thermal inertia, which leads to a high energy saving and comfort.

TUV & CE EN-442 Certified

Steel Panel Radiators for Central Heating are available in different sizes, with diverse backgrounds and measurements.

The best quality

The Steel Panel Radiator for Home Central Heating of ALL THERM are doubly painted through an anti corrosion layer via a cataphoresis process and then the second treatment is a painting coat “epoxi” followed by a high temperature drying process for a perfect finish. ALL THERM use the most advanced and up-to-date technology following a strict CE EN-442 certification and manufacturing controlled by TUV and Eurovent Certita. These processes ensure a perfect finish and very high durability over time.

Our special Steel Panel Radiator highest quality provides a long-life service with a 10-year guaranty for manufacturing defects.

High thermal performance

The great power of thermal transmission of steel cause high emission of heat with low energy consumption.

Our quality control department performs constant and rigorous tests on each element with a maximum working pressure of 8 bar.

Modern design

This Steel Panel Radiator for Home Central Heating has a standard design and distribution of heat. A perfect finish and durability, thanks to the painting by double cataphoresis electrophoresis (immersion) and subsequent high temperature drying under pressure.

Steel Panel Radiators for Home Central Heating are easy install.

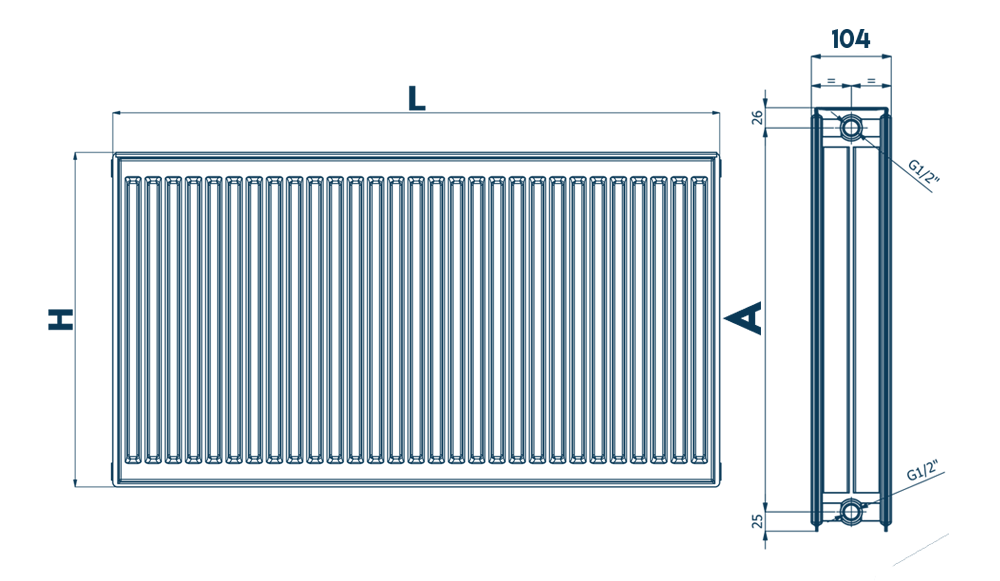

Install in horizontal mural

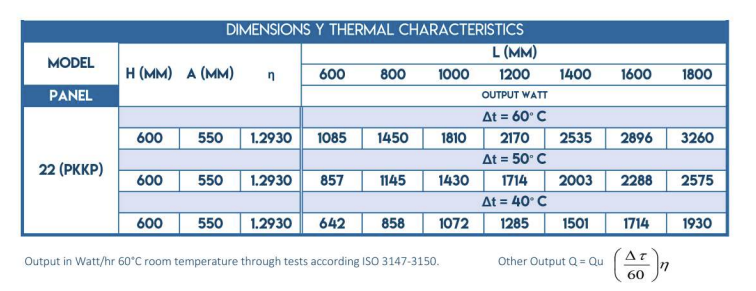

The Steel Panel Radiator is available from 600 to 1800 mm length and 400, 555 or 600 mm height. All protected by a retractable plastic cover and with side guards which saves on labor and protects the goods until delivery.

ALL THERM Panel Steel Radiator is CE certified by TUV Intercert Saar and also AFNOR EUROVENT CERTITA NF.

Is the Aluminium Radiator painted?

ALL THERM Steel Panel Radiators are are doubly painted through an anti corrosion layer via a cataphoresis process and then the second treatment is a painting coat “epoxi” followed by a high temperature drying process for a perfect finish.